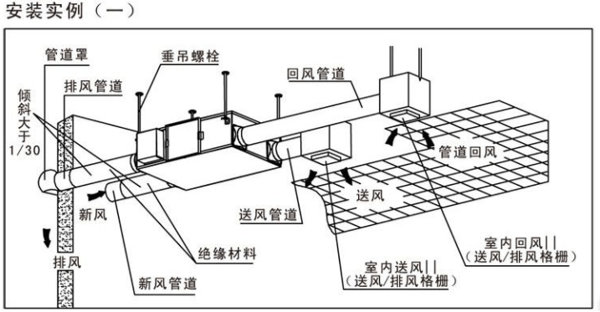

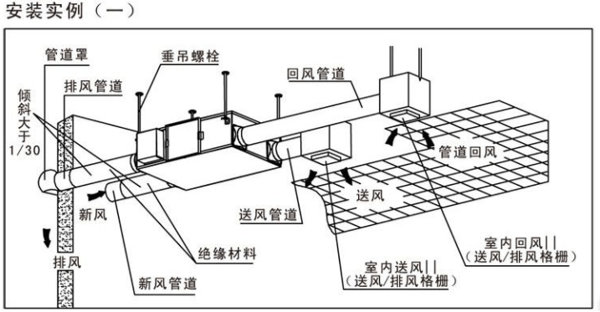

Now, energy recovery ventilator systems are generally installed in various places, many repair teams, hydropower installation teams are engaged in the installation of new full heat exchange fans, however, in these

installation teams, there is no professional design and installation personnel, they lack the basic knowledge of installation. This paper summarizes the common problems and solutions in the installation practice of energy recovery ventilator, and provides reference for users who lack the installation experience of new total heat exchange fans:

1. Minimize the number of pipe turns;

2. Maximize the turning radius of the pipeline;

3. If the pipe is too long, the installation cost will be too high, and the air supply effect will become worse. It is better to add a host machine, but the cost will be lower.

4. The installation location of the main engine should be as close as possible to the outdoor air inlet and outlet;

5. Rubber cushion or shock absorber spring shall be used in the hoisting position of the main engine for shock absorber;

6. The connection between the main engine and the pipeline shall be made of canvas to prevent vibration and noise;

Installation procedure of energy recovery ventilator system

The first step is to drill the wall when installing the fresh air system. The purpose of drilling is conducive to the direction of the pipeline. Therefore, drilling must be completed before the installation of the main engine. Generally, it is better to finish the drilling one day before the construction. If the user has finished the decoration of the house, we must do a good job of protection before drilling. The size of the hole is determined by the size of the pipeline, and the location should be accurate according to the construction drawings and the actual situation of the site.

The second step is to install the air outlet for the whole house using the new air system. It is suggested that a room should adopt the form of one inlet and one outlet, and the installation location should be diagonal. The installation position of the air inlet should meet the requirements of the design drawings. The air inlet should be installed in the easy-to-install position as far as possible, and the dead angle should be avoided, so that fresh air and indoor dirty air can form a circulating system and keep the continuous circulation of indoor air. The exhaust outlet is installed on the ceiling of the toilet and corridor. The indoor air enters the main engine through the exhaust outlet, and then is discharged outdoors through the main engine. It is better to keep the distance between the exhaust port and the intake port between 2m and 3m to ensure that the exchanged air will not mix together.

Step 3: start up and debug after the installation of fresh air system project, the machine needs to be debugged. The debugging mainly includes the safety inspection before operation, the test run of the fan in the main and external machine of the fresh air unit, check whether the fresh air system is running smoothly and whether there is abnormal vibration and sound. The final debugging result shall be accepted by the owner. From the above installation steps of fresh air system for full heat

exchanger, the installation of fresh air system is not complicated, but the installation specification cannot be ignored. Standard installation can maximize the ventilation and ventilation of fresh air system, improve air quality function; Unreasonable installation can make its use effect discount greatly.