4 system ensure higher precision,stability temperature and humidity(Cooling,Heating,Dehumidification, Humidification )

Using cycling vapor compression refrigeration system,when the compressor work, indraft low temperature and pressure refrigerant gas from evaporator, compressed by compressor into high temperature and pressure gas, and then into the condenser to condense into liquid, meantime release heat, after throttling under the function of the thermal expansion valve, entering into the evaporator and absorbed heat,then evaporate into gas, finally back to the compressor through the suction tube and complete a refrigeration cycle ; On the other hand,through changing of refrigerant flow direction, total or partial condensing heat generated from refrigeration can be exhausted to outside,to achieve the purpose of adjusting the indoor temperature.

When the wet air flows through the evaporator surface, the air temperature will drop, when it falls below the dew point,the steam in the air will condense out, gathering and drainage of water pipes in the receiving plate, the controller automatically adjusts the compressor start-up time according to the setting humidity , so as to achieve the purpose of adjusting humidity.

It adopts PTC heating method, which is safe and efficient. It is divided into 2 levels of heating, and the start point and stop point of each level of heating can be set freely.

1. When the temperature difference is large, the second-level heating is input, and the temperature rises quickly

2. When the temperature difference is small, the heating level is 1 to keep the temperature rising.

3. During dehumidification, it is used as auxiliary heat input to maintain stable temperature.

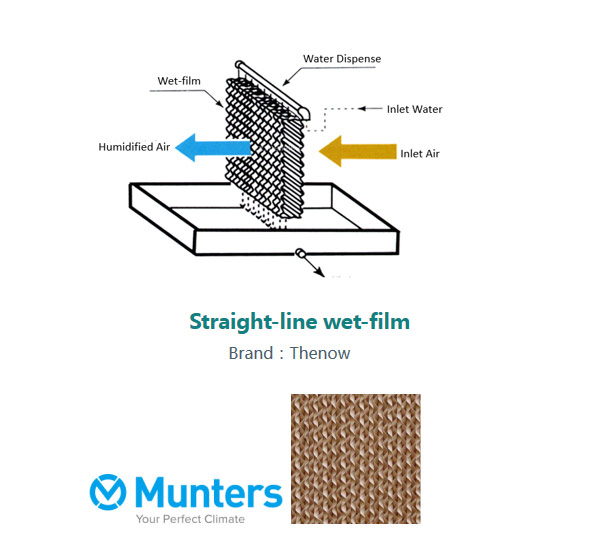

A super absorbent composite inorganic material using inorganic fibers as a base material, which is made by soaking and sintering a special component resin. The requirement of evaporative humidification for the water source is only tap water, and no special treatment is required. Water does not rely on mechanical external forces on the surface of the humidifying medium, and is directly volatilized into water molecules in the form of air. It does not require absorption space. Even if the opening control of the classification is not adjusted, the amount of humidification of the air will automatically increase or decrease with the level of air drying, and no supersaturated humidification will occur.

1. High water absorption, 100Kg water absorption per cubic meter of medium,

2. Self-cleaning function

3. Flame retardant test conforms to JIS A1332 standard and UL900 fire safety standard.

4.The mould resistance test is qualified and conforms to JIS Z2911 standard.

5. GREENGUARD certification.

The unit collects the temperature and humidity values of the return air in real time, and compares them with the target temperature and humidity values set by the customer. The system first implements the principle of temperature priority, first solves the temperature, and achieves the temperature by cooling and heating balance, then automatically handles the humidity Through the balance of dehumidification and humidification, the humidity is balanced, and the indoor heat insulation, heat insulation, and high air tightness are used to achieve indoor temperature and humidity stability.